Safety Glasses: Ensuring Eye Protection in Work Environments

Introduction

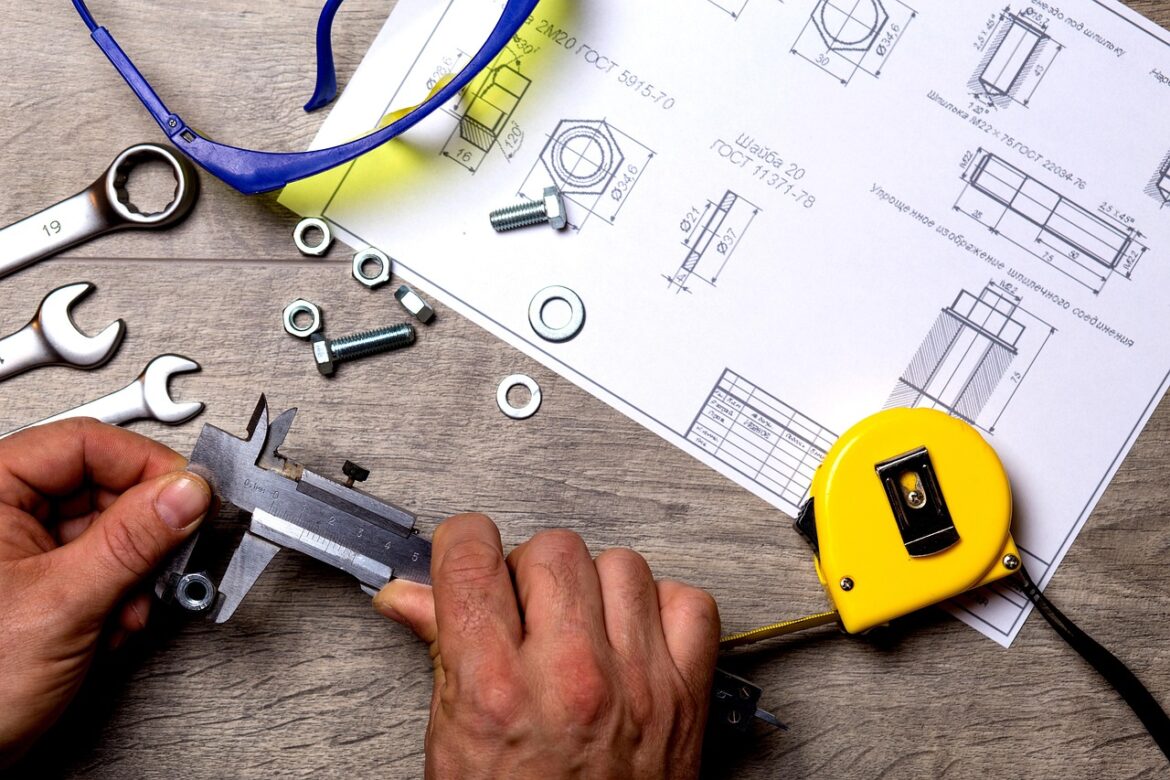

In industries ranging from construction to laboratory work, maintaining safety standards is not just about compliance, but about ensuring the well-being of all personnel. One of the most crucial aspects of personal protective equipment (PPE) is the use of safety glasses. Safety Glasses: Ensuring Eye Protection in Work Environments is more than a slogan; it’s a fundamental practice that helps prevent painful and potentially permanent eye injuries. Whether they’re flying debris or chemical splashes, the hazards present in work environments make it imperative to understand the use, types, and maintenance of safety glasses.

Why Are Safety Glasses Crucial in Work Environments?

Eyes are extremely vulnerable to various hazards at the workplace. Physical debris such as dust, wood chips, and metal shards can cause surface scratches or more severe damage like punctures. Chemical substances pose risks of splashes, which can lead to painful injuries or vision loss. Even exposure to harmful radiation and UV rays in some work environments can deteriorate vision over time. Safety glasses act as a first line of defense against these threats, designed specifically to withstand impacts and shields against hazardous exposures.

Choosing the Right Safety Glasses

Types of Safety Glasses:

- Polycarbonate Lenses: These are the most common materials used due to their impact resistance and lightweight properties. They offer UV protection making them suitable for both indoor and outdoor use.

- Polarized Lenses: Ideal for work environments with high levels of glare; these lenses help reduce eye strain and increase visibility.

- Prescription Safety Glasses: For workers who need corrective lenses, prescription safety glasses are customized to provide vision assistance while ensuring all-around protection.

- Goggles: When a seal against the face is necessary, particularly against chemical exposure or fine airborne particles, safety goggles are the preferred choice.

Lens Coating: Anti-fog, anti-scratch, and anti-reflective coatings are additional features that can enhance the functionality and durability of safety glasses.

Best Practices for Using Safety Glasses

- Proper Fit: Ensure that safety glasses fit securely and comfortably. They should not slip off your face nor should they pinch or press too tightly.

- Regular Inspection: Before each use, inspect glasses for any scratches or cracks. Damaged lenses can compromise protection and might impair vision.

- Clean Regularly: Follow manufacturer guidelines for cleaning. Improper methods can damage lens coatings. Use mild soap and water or lens cleaning solutions and a soft cloth.

- Immediate Replacement: Replace safety glasses immediately if they become damaged or if the visibility is compromised.

Maintenance of Safety Glasses

Keeping your safety glasses in top condition is essential for them to perform effectively. Store them in a clean, dry place away from exposure to direct sunlight or extreme temperatures. In addition, training sessions on the correct usage, maintenance, and necessity of safety glasses can instill a sense of importance and encourage compliance among workers.

FAQs: Safety Glasses: Ensuring Eye Protection in Work Environments

Q1: Are safety glasses required for all types of work environments?

A1: While not all work environments may require the use of safety glasses, they are crucial in places with mechanical, chemical, or radiological hazards. It’s best to conduct a hazard assessment to determine the need for eye protection.

Q2: Can I wear regular glasses instead of safety glasses for protection?

A2: Regular glasses do not offer the same level of protection as safety glasses. Safety glasses have a stronger build and specific design features, such as side shields, to protect against workplace hazards.

Q3: How often should safety glasses be replaced?

A3: There is no one-size-fits-all answer as it depends on the frequency of use and the exposure to harmful conditions. Regular inspections will help determine when replacements are necessary.

Q4: Are there safety glasses available for different light conditions?

A4: Yes, safety glasses come with different tints for various light conditions. For example, amber lenses are beneficial in low-light conditions as they enhance contrast.

Conclusion

Safety Glasses: Ensuring Eye Protection in Work Environments is not merely about following regulations; it’s about safeguarding one of the most vital senses — your sight. The right safety glasses for the right job can be the difference between a normal day at work and a life-altering injury. Hence, understanding, choosing, and properly maintaining safety glasses should be a paramount concern for workers and employers alike. After all, effective safety practices are not just seen; they are felt by everyone in the safer, more secure working environment they create. Remember, when it comes to protective eyewear, there’s no such thing as being too safe.